Reliable Testing for Quality Assurance

We know that when it comes to steel, quality and reliability are non-negotiable. That’s why we offer material testing as an additional service for our clients, ensuring that every product we deliver meets the standards you need for your projects to succeed. Whether you’re working in shipbuilding, heavy industry, or the Oil & Gas industry, our testing services provide that extra layer of confidence. To ensure the highest quality and variety of testing, we also enlist the services of our trusted partner, Qlab.

Testing methods we offer

Our Non-Destructive Testing (NDT) services are designed to ensure your materials perform as expected without causing any damage during the inspection process. Here’s a look at the different methods we offer:

Visual Inspection (VI): Sometimes, it’s the simplest checks that make all the difference. Our trained inspectors carefully review materials for any surface flaws or irregularities.

Ultrasonic Testing (UT): Using sound waves, we can inspect beneath the surface of materials to detect internal defects that may not be visible.

Dye or Liquid Penetrant Inspection (PT/DPI): This method highlights surface cracks or imperfections by applying a dye or liquid to the material, ensuring nothing is missed.

Magnetic Particle Inspection (MPI): For ferromagnetic materials, we use magnetic fields to identify any discontinuities, ensuring safety and structural soundness.

Positive Material Identification (PMI): Knowing the exact composition of your materials is key. With PMI, we verify that the material matches your project specifications.

Cladding Thickness Report (CTR): Accurate measurements of cladding thickness help ensure durability and longevity, especially in demanding environments.

Qlab

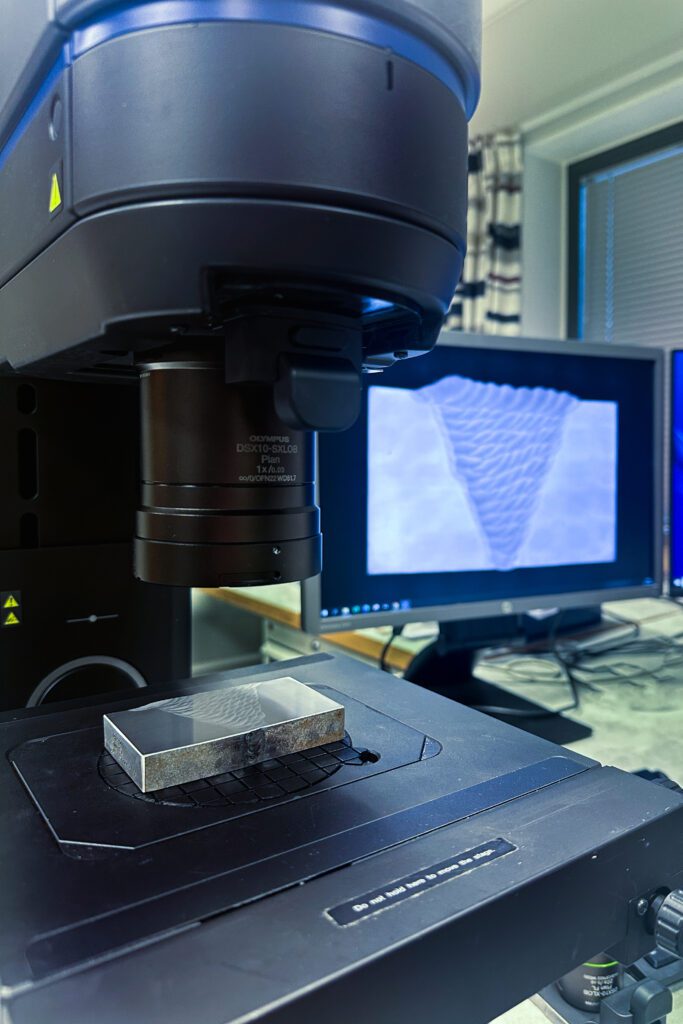

Qlab is a highly trusted partner with a stellar reputation in the industry. Luckily for us, they’re located nearby and have supported our material testing services over the years. Qlab is a full-service provider of inspection and testing services, offering highly modernized machinery that benefits our clients.

– Our collaboration with Qlab has elevated our NDT testing services. With the help of their machinery, we can deliver trusted material testing to our clients, no matter what specifications are required or which industry they are working in, says Harald Heyeraas, Sales & Project Manager at Arctic Steel.

Why material testing matters

Material testing isn’t just an extra step, it’s part of making sure your project runs smoothly and safely. We understand that every project has its own unique requirements, and our testing services are here to help you meet those specifications. Whether you need a quick check or a more thorough analysis, we’re ready to assist.

At Arctic Steel, we see material testing as a way to give our clients peace of mind. You can trust that our testing processes, aided by the professionals at Qlab, are thorough, precise, and conducted by experienced personnel who understand the importance of getting things right.