AISI 4330 – A High-Strength Alloy Steel for Extreme Demands

AISI 4330 is a low-alloy, high-strength steel known for its outstanding toughness, fatigue resistance, and hardenability. With a carefully balanced mix of nickel, chromium, and molybdenum, this alloy performs exceptionally well under mechanical stress and in severe service conditions.

Compared to more common grades like AISI 4140 and AISI 4145, AISI 4330 offers higher toughness and improved fatigue strength, especially in larger cross-sections. This makes it a valuable alternative when enhanced durability and performance are critical.

Key Properties of AISI 4330 Steel

AISI 4330 provides a dependable blend of strength and ductility, even at elevated hardness levels. Its enhanced alloying content gives it greater through-hardening capability than AISI 4140 or 4145, allowing it to maintain consistent mechanical properties throughout thicker components.

Key characteristics include:

- High tensile strength and toughness – Maintains ductility even under extreme stress.

- Excellent fatigue resistance – Withstands cyclic loading and shock.

- Good through-hardening capability – Suitable for larger or more complex shapes.

- Improved hardenability over AISI 4140/4145 – Thanks to increased nickel content.

This makes AISI 4330 an excellent choice for demanding components that must deliver both strength and resilience.

Common Applications of AISI 4330 Steel

Because of its robust mechanical properties and reliability under load, AISI 4330 is used in a range of high-performance industrial applications. It is particularly suitable for components subjected to high mechanical stress, pressure, or torsion — where performance cannot be compromised.

Typical uses include shafts, fasteners, couplings, heavy-duty connectors, lifting tools, and other structural parts where toughness and fatigue resistance are essential. Its ability to withstand repeated stress without failure makes it ideal for both dynamic and static applications in challenging environments.

Benefits of Using AISI 4330

Choosing AISI 4330 comes with several performance and longevity advantages:

- Superior strength-to-weight ratio – Enables lighter yet stronger components.

- Reliability under repeated load – Excellent for high-torque and high-cycle applications.

- Heat treatable to multiple strength levels – Adaptable to specific application demands.

- Long service life – High resistance to wear, fatigue, and cracking.

- Customizable chemistry and cleanliness (4330MOD / 4330V) – For enhanced consistency and specific performance targets.

This combination of durability and adaptability makes AISI 4330 a dependable material for industries that demand more from their steel.

Why Choose Arctic Steel’s AISI 4330?

At Arctic Steel, we deliver high-quality AISI 4330 steel tailored for tough environments and strict technical specifications. Our materials are supplied with close control of mechanical properties, traceability, and consistent quality, ensuring dependable performance in every project.

Whether you’re operating in energy, offshore, or heavy industrial sectors, Arctic Steel’s AISI 4330 provides the strength and reliability you need. With our commitment to precision and service, you can count on materials that meet both your operational and safety requirements.

AISI 4140 – A Versatile Alloy Steel for Demanding Applications

AISI 4140 is a chromium-molybdenum alloy steel known for its remarkable combination of strength, toughness, and fatigue resistance. It’s a general-purpose workhorse. Part of the same 41xx family as Arctic Steel’s AISI 4145H MOD, AISI 4140 offers a slightly lower carbon content and is widely used across sectors that require reliable performance under mechanical stress and thermal exposure.

Thanks to its excellent balance of properties, AISI 4140 is a go-to material for high-performance applications in industries such as oil & gas, automotive, power generation, and general engineering.

Key Properties of AISI 4140 Steel

AISI 4140 (UNS G41400 / EN 1.7223) offers high tensile strength, good ductility, and strong wear resistance. It can be supplied in a variety of conditions, including annealed, normalized, quenched and tempered (Q&T), or as heat-treated forgings or bars — depending on end-use requirements.

Typical properties of AISI 4140 include:

- Excellent hardenability – Suitable for heat treatment to achieve high strength levels.

- Good toughness and fatigue resistance – Performs well under cyclic loads and dynamic stresses.

- Moderate corrosion resistance – Can be improved with coatings or surface treatments.

- High tensile strength – Often in the range of 850–1000 MPa in Q&T condition.

- Machinability and weldability – Good machinability; weldable with proper precautions.

Its mechanical performance can be adjusted through heat treatment, making it a highly flexible material option.

Common Applications of AISI 4140 Steel

Thanks to its versatile properties, AISI 4140 is widely used across several demanding industries. In the oil and gas sector, it is commonly applied in components such as shafts, downhole tools, and connection parts, particularly where resistance to fatigue and wear is essential.

In power generation, AISI 4140 is often used for rotors, spindles, and other high-load components exposed to dynamic forces. The automotive and transportation industries rely on this alloy for critical parts like crankshafts, gears, axles, and suspension elements, where both strength and durability are required.

Heavy equipment manufacturers also favor AISI 4140 for structural components, high-strength bolts, and precision tooling. In general engineering, it serves well in applications such as rollers, molds, and fixtures that demand consistent mechanical performance.

Its balanced alloy composition provides the strength typically associated with high-carbon steels, but with reduced brittleness, making it suitable for both static and dynamically loaded applications.

Benefits of Using AISI 4140

When performance and adaptability matter, AISI 4140 offers several clear advantages:

- Strong and tough – Withstands high mechanical loads and fatigue cycles.

- Heat-treatable – Offers a wide range of hardness and strength options.

- Wear-resistant – Suitable for parts that experience friction or impact.

- Cost-effective – Combines performance and economy, especially in large-scale applications.

- Available in multiple forms – Including bars, forgings, and machined components.

Why Choose Arctic Steel’s AISI 4140?

At Arctic Steel, we supply premium-quality AISI 4140 with tight control on chemical composition and mechanical properties. Whether you need raw material for machining or pre-treated components ready for use, our 4140 is manufactured to meet high industry standards and client-specific requirements.

Our quality assurance processes ensure that every batch delivers the strength, performance, and reliability that your application demands, even in the most challenging environments.

AISI 420M NACE – A Corrosion-Resistant Steel for Critical Applications

AISI 420M NACE is a high-strength martensitic stainless steel alloy developed for use in sour service environments, particularly in the oil and gas industry. Known for its excellent resistance to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC), this alloy meets the demanding requirements of NACE MR0175/ISO 15156, the industry standard for materials in H₂S-containing environments.

With a carefully controlled chemical composition and enhanced mechanical properties, AISI 420M NACE is a go-to choice for components exposed to both mechanical stress and corrosive elements.

Key Properties of AISI 420M NACE

AISI 420M is a modified version of the standard AISI 420, engineered to perform under sour service conditions where hydrogen sulfide (H₂S) is present. This steel is specially heat-treated to achieve high strength without compromising its resistance to environmental cracking. Key characteristics include:

- Compliance with NACE MR0175/ISO 15156 – making it suitable for sour service.

- Good resistance to sulfide stress corrosion and pitting.

- Controlled hardness – to remain within NACE limits, generally ≤ 22 HRC.

- Improved toughness for a martensitic grade, with good performance even in challenging environments.

These properties make 420M NACE well-suited for severe applications where both mechanical and corrosion challenges coexist.

Common Applications of AISI 420M NACE

Because of its unique blend of mechanical strength and corrosion resistance, AISI 420M NACE is widely used in industries where safety and durability are non-negotiable. Typical applications include:

- Oil & Gas industry – Valve components, downhole tools, and connectors in sour wells where resistance to SSC is essential.

- Subsea equipment – Components exposed to seawater and H₂S, such as flanges and shafts.

- Chemical processing – Parts requiring resistance to aggressive media in refining and petrochemical environments.

- Pumps and valves – Particularly in offshore and upstream applications.

Benefits of Using AISI 420M NACE

- Reliable in H₂S-rich environments – Prevents catastrophic failure due to sulfide stress corrosion.

- Versatile strength – High mechanical properties without compromising corrosion resistance.

- Strict quality control – Ensures consistent material performance across demanding conditions.

- Low maintenance costs – Superior durability extends equipment life, reducing downtime and repairs.

Why Choose Arctic Steel’s AISI 420M NACE?

At Arctic Steel, we deliver steel that performs when it matters most. Our AISI 420M NACE materials are manufactured to the highest quality standards, with full traceability and compliance with NACE requirements. Whether you’re operating offshore, onshore, or subsea, we provide steel solutions designed to meet your exact specifications.

Our Very Own Man of Steel

Meet Jonas Bolstad Scheie! Our CEO, steel enthusiast, and loyal supporter of Bryne FK.

Jonas officially took the helm at Arctic Steel in 2021 after the steel department forged its own way by becoming their own company, but his story in the steel world started long before that. In fact, you could say it began with a purchase order for 4140 tubing back in 2012 – a humble yet heartfelt start to a steel-filled career.

From forged parts to forming strategy

Jonas’s steel journey began in Aarbakke’s purchasing department, where he focused on forged goods from Italy. Working side by side with production, he developed a deep appreciation for the process – how raw materials are transformed into precision parts with real-world impact.

– It was a great foundation. You learn quickly when you’re that close to both the technical details and the people who make it all happen, Jonas reflects.

Fast-forward a few years, and Jonas found himself leading Arctic Steel – a growing company that supplies specialty materials to industries where quality and reliability are non-negotiable.

– The transition from Purchaser to CEO has been both exciting and demanding. Arctic Steel has had the benefit of being part of the Aarbakke ecosystem starting out as a department in the company. Later, we’ve had the chance to carve out our own path and building a business identity of our own, he admits.

A CEO who leads from the middle

Jonas’s leadership style isn’t about corner offices or top-down commands. It’s more about alignment, accessibility, and knowing when to step in – and when to step back.

– As CEO, I’m responsible for setting the overall strategy and making sure our team has what they need to succeed. That means staying close to both the people and the numbers, he explains.

He’s quick to credit the team for Arctic Steel’s momentum.

– We have a group of incredibly capable, committed people here. It’s easy to lead when the team is already this strong.

Culture, connection – and just the right amount of chaos

If you ask Jonas what really makes Arctic Steel tick, he won’t hesitate: it’s the people.

– There’s something special about the culture we’ve built here. We’ve got a strong sense of unity, a lot of mutual respect, and a shared willingness to help each other out – no matter what comes up, he says.

This culture isn’t just something that happens organically. It’s shaped every day through collaboration, transparency, and a shared pride in the work.

– Everyone here knows their role, but we also pitch in across departments. We celebrate wins together – big and small – and we’re not afraid to laugh at ourselves once in a while.

That sense of humor shows up often, especially on Mondays after a weekend of football.

Football rivalries and Friday laughs

In a workplace full of strong opinions, one debate consistently reigns supreme: football.

With colleagues supporting local rival teams like Viking FK and Bryne FK, and Manchester United and Liverpool in the Premiere League, it’s safe to say things can get lively.

– There’s definitely some healthy competition when it comes to football. Andre and I don’t always see eye to eye on which team deserves the glory, but it’s all in good fun, Jonas explains with a laugh.

He proudly waves the Bryne FK flag, while also managing to keep the peace – most of the time.

– The national team breaks are the only weeks we all agree on something. But once Eliteserien is back, the gloves come off. In the most collegial way, of course, he jokes.

Listening, learning, and long-term relationships

When it comes to customers, Jonas and the Arctic Steel team approach every collaboration with care.

– We put a lot of effort into understanding what our customers actually need – not just what they’re asking for. Whether it’s a standard product or a rare steel grade with tight tolerances, we aim to deliver the right solution, on time, every time, Jonas explains.

That level of dedication is why many clients return again and again.

– Long-term relationships are everything in this business. And those relationships are built on availability, trust, and follow-up. We work hard to stay close to our customers, not just in the sales phase, but throughout the entire process, Jonas explains.

A soft spot for 4140

In case you were wondering: yes, Jonas has a favorite steel grade. Of course he does.

– It’s 4140 tubing. It was the first material I ever purchased back in 2012. There’s a bit of sentimental value there, he says with a smile.

He might joke about it, but there’s something fitting about a CEO who remembers his first steel order as fondly as most people remember their first car.

From Crafting Windows to Delivering Specialty Steel

Meet Harald Heyeraas, one of the latest additions to the Arctic Steel team, who has now been with us for a year! As a Sales & Project Manager, he’s here to help customers navigate the world of specialty steel – with a personal touch. With a background that spans both hands-on craftsmanship and strategic sales, Harald brings a fresh perspective to the team.

From wooden frames to steel beams

Before joining Arctic Steel, Harald spent an impressive 16.5 years at Gilje Tre, a leading window and door manufacturer. He started on the shop floor at just 14 years old, working his way up through different roles before settling into sales. With a trade certificate in woodworking and building interiors, he knows the value of precision and quality – skills that translate surprisingly well into the steel industry.

A Sales & Project Manager with a personal approach

Harald’s role at Arctic Steel isn’t just about numbers and logistics – it’s about people. One of his goals is to understand customer needs and offer a tailored solution that makes their job easier.

– What I really appreciate here is that we follow the customer all the way from the first inquiry to final documentation. It’s a much more personal process, he explains.

Unlike larger companies, Arctic Steel likes to keep their service personalized by designating project managers to dedicated projects from start to finish.

– I think that personal touch adds real value. Customers know exactly who to call, and they don’t get lost in a system, Harald says.

The customer portal – a game changer

One of the features Harald is most excited about is Arctic Steel’s customer portal.

– It’s fantastic! Customers can log in, browse our inventory, and even find rare materials we have in stock. They can send an inquiry, and in many cases, we can have the order ready for pickup or shipping the same day, he explains.

The portal gives customers the flexibility to search for what they need at their own convenience. And with their new facilities under construction a new solution for a 24/7 material pick up may be in place later this year.

Finding his footing (and his football rivalries)

Though he’s been with Arctic Steel for just a year, Harald already feels at home – and not just because his colleagues invited him to a hockey game before his first day! The company culture is welcoming, and the strong team spirit makes every day enjoyable.

– I was even invited to the Christmas dinner before I officially started. That says a lot about how inclusive this place is.

When he’s not at work, Harald keeps busy with family life. His seven-year-old son has already been introduced to football culture, and Harald takes him to Bryne matches to support the local team. But make no mistake – Harald’s heart beats for Rosenborg and Liverpool.

– I support the only Norwegian club with two stars over their logo, he says proudly.

Football discussions in the office are lively, especially with Henning and Jonas supporting Manchester United.

A new challenge every day

With so many new materials, specifications, and industry nuances to learn, Harald admits that the transition into the steel industry has been a steep learning curve – but that’s exactly what makes it exciting.

– At my old job, I knew everything. Here, I’m constantly learning something new, and I love it!

Luckily, he has seasoned colleagues to lean on.

– We have some real experts here, and they’ve been incredibly helpful. It’s a great environment to learn and grow.

A man of wood who’s found a love for steel

And speaking of steel – does Harald have a favorite grade yet?

– As someone who spent years working with wood, I find it fascinating how dense and heavy some steel types are. The weight-to-size ratio is mind-blowing.

His current pick? Inconel – a high-performance alloy that commands an equally high price.

– Coming from the world of timber, seeing some of these price tags has been an eye-opener, he laughs.

With a blend of technical expertise, sales know-how, and a down-to-earth personality, Harald is already proving to be a great addition to Arctic Steel. And whether he’s helping customers find the right steel or discussing football rivalries in the office, one thing’s for sure – he’s here to make an impact.

Understanding AISI 4145 Steel – Properties, Applications, and Benefits

AISI 4145 is a chromium-molybdenum low alloy steel renowned for its exceptional strength, durability, and toughness. It belongs to the 41xx family of steels, which are widely used across various industries due to their versatility and reliability. Let’s explore key properties, applications, and benefits of the AISI 4145 steel, and more specifically the AISI 4145H MOD quality that Arctic Steel offers.

Key Properties of AISI 4145 Steel

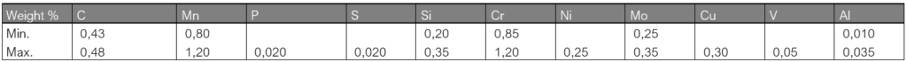

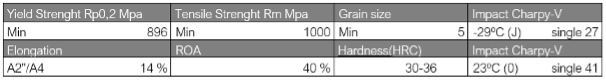

AISI 4145 steel is characterized by its high hardenability and excellent wear resistance, making it suitable for heavy-duty applications. Arctic Steel’s AISI 4145H MOD / EN 1.7225 stands out with the following specific chemical composition:

In addition to its chemical makeup, Arctic Steel’s AISI 4145H MOD / EN 1.7225 also delivers outstanding mechanical properties:

These specific attributes ensure that Arctic Steel’s AISI 4145H MOD / EN 1.7225 can meet the stringent demands of various industries, offering consistent quality and performance.

Common Applications of AISI 4145 Steel

Due to its robust properties, AISI 4145 is commonly used in industries that demand high-performance materials. Typical applications include:

- Oil and Gas Industry: AISI 4145 is a staple in drilling tools, such as drill collars, tool joints, and rotary tables, thanks to its ability to withstand high stress and wear.

- Power Generation: The steel is often used in shafts and other critical components exposed to dynamic forces.

- Automotive and Aerospace Industries: It’s used in parts requiring a balance of strength, toughness, and wear resistance, such as gears, shafts, and fasteners.

- Heavy Machinery: Components like crankshafts, axles, and other machine parts benefit from the durability and resilience of AISI 4145 steel.

Benefits of Using AISI 4145 Steel

Choosing AISI 4145 steel comes with several advantages, particularly for applications where performance and longevity are paramount. Key benefits include:

- Reliability in harsh environments: The steel’s toughness and wear resistance make it ideal for extreme conditions, such as those found in oilfields or heavy industrial settings.

- Customizability through heat treatment: AISI 4145 can be tailored to meet specific performance requirements by adjusting its heat treatment process.

- Consistent mechanical properties: Arctic Steel’s stringent quality control ensures reliable strength, toughness, and impact resistance.

- Cost-effectiveness: Its durability and long service life often result in lower maintenance and replacement costs over time.

Why Choose Arctic Steel’s AISI 4145H MOD / EN 1.7225?

At Arctic Steel, we specialize in delivering high-quality steel products tailored to your needs. Our AISI 4145 steel meets stringent quality standards and is manufactured with precision to ensure optimal performance. With its verified chemical composition and exceptional mechanical properties, Arctic Steel’s AISI 4145H MOD / EN 1.7225 stands as a reliable solution for even the most demanding applications.

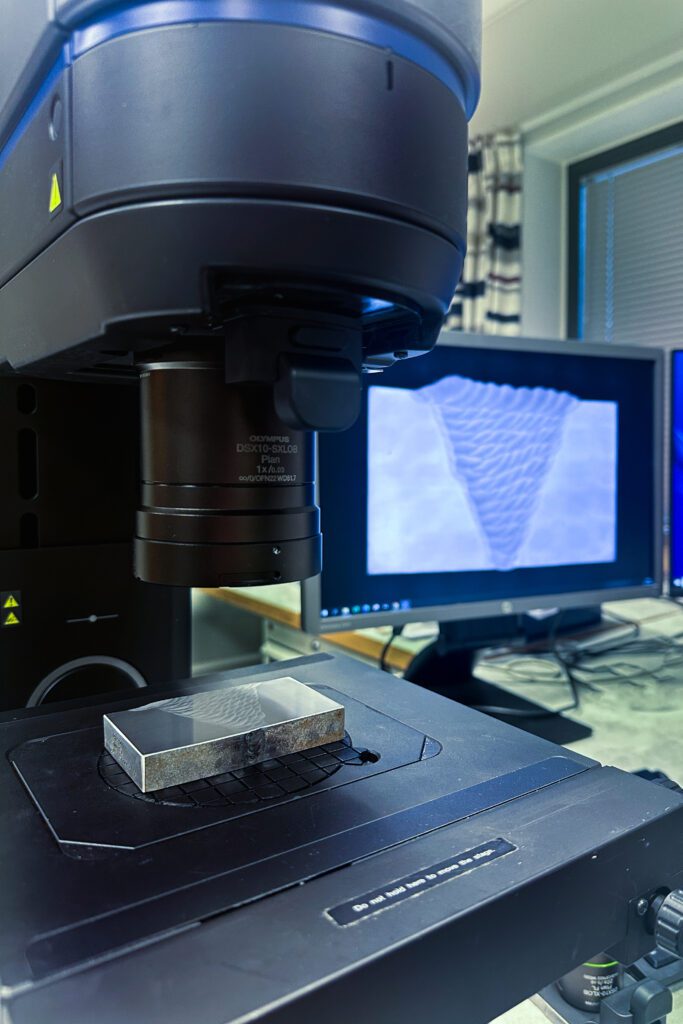

Reliable Testing for Quality Assurance

We know that when it comes to steel, quality and reliability are non-negotiable. That’s why we offer material testing as an additional service for our clients, ensuring that every product we deliver meets the standards you need for your projects to succeed. Whether you’re working in shipbuilding, heavy industry, or the Oil & Gas industry, our testing services provide that extra layer of confidence. To ensure the highest quality and variety of testing, we also enlist the services of our trusted partner, Qlab.

Testing methods we offer

Our Non-Destructive Testing (NDT) services are designed to ensure your materials perform as expected without causing any damage during the inspection process. Here’s a look at the different methods we offer:

Visual Inspection (VI): Sometimes, it’s the simplest checks that make all the difference. Our trained inspectors carefully review materials for any surface flaws or irregularities.

Ultrasonic Testing (UT): Using sound waves, we can inspect beneath the surface of materials to detect internal defects that may not be visible.

Dye or Liquid Penetrant Inspection (PT/DPI): This method highlights surface cracks or imperfections by applying a dye or liquid to the material, ensuring nothing is missed.

Magnetic Particle Inspection (MPI): For ferromagnetic materials, we use magnetic fields to identify any discontinuities, ensuring safety and structural soundness.

Positive Material Identification (PMI): Knowing the exact composition of your materials is key. With PMI, we verify that the material matches your project specifications.

Cladding Thickness Report (CTR): Accurate measurements of cladding thickness help ensure durability and longevity, especially in demanding environments.

Qlab

Qlab is a highly trusted partner with a stellar reputation in the industry. Luckily for us, they’re located nearby and have supported our material testing services over the years. Qlab is a full-service provider of inspection and testing services, offering highly modernized machinery that benefits our clients.

– Our collaboration with Qlab has elevated our NDT testing services. With the help of their machinery, we can deliver trusted material testing to our clients, no matter what specifications are required or which industry they are working in, says Harald Heyeraas, Sales & Project Manager at Arctic Steel.

Why material testing matters

Material testing isn’t just an extra step, it’s part of making sure your project runs smoothly and safely. We understand that every project has its own unique requirements, and our testing services are here to help you meet those specifications. Whether you need a quick check or a more thorough analysis, we’re ready to assist.

At Arctic Steel, we see material testing as a way to give our clients peace of mind. You can trust that our testing processes, aided by the professionals at Qlab, are thorough, precise, and conducted by experienced personnel who understand the importance of getting things right.

Steel, Sales, and Some Serious Passion for Football

Meet Dan Stian Johnsen, our dynamic Sales & Project Manager at Arctic Steel, who joined us in February 2023. Dan Stian’s career journey, brimming with hands-on expertise and a flair for sales, has made him a perfect fit for Arctic Steel. Plus, his humor and love for teamwork add a spark to our daily office life.

A career forged in steel (and sales)

Dan Stian’s path to Arctic Steel is a tale of well-rounded experience. Starting at Øglænd System, where he spent over a decade, Dan Stian earned his trade certificate as a machine operator and soaked up valuable technical knowledge. Then came five years at Mc Lea, where he led sales, logistics, and retail operations – honing his customer-focused approach.

– Øglænd System gave me the technical know-how, and Mc Lea taught me sales. It’s the ultimate combo for my role at Arctic Steel, Dan Stian reflects.

A day in the life of a Sales & Project Manager

In his role, Dan Stian manages a blend of client relationships, project follow-ups, and supplier coordination. Every day presents fresh challenges, from pricing new projects to tackling customer meetings or ensuring deliveries hit the mark.

– No two days are the same. Some projects feel like a sprint, while others are more of a marathon, Dan Stian explains.

And thanks to Arctic Steel’s tight-knit team, building strong relationships comes naturally – whether through shared laughs in the office or bonding at industry events.

Conferences, trade shows, and building bridges

Part of Dan Stian’s role at Arctic Steel includes traveling to conferences and steel trade shows – a perk he embraces with enthusiasm. For Dan Stian, these events aren’t just about showcasing Arctic Steel’s capabilities, they’re opportunities to connect with clients and suppliers in a way that email or phone calls simply can’t replicate.

– Traveling to trade shows gives us a chance to put faces to names and truly understand our clients’ and suppliers’ needs. It’s about building relationships that last beyond the next transaction, Dan Stian explains.

Whether it’s discussing upcoming projects over a cup of coffee at a bustling trade show booth or networking at industry dinners, Dan Stian thrives in the social aspect of his work. These connections often lead to better collaboration, more tailored solutions, and a stronger rapport with the people Arctic Steel serves.

Rewarding projects

When asked about recent rewarding projects, Dan Stian highlights his work with Prosess Metall, Arctic Steel’s newly acquired company. He has been tasked with the onboarding of their new clients and making sure the transition goes smoothly for everyone involved.

This fall Arctic Steel has been working together with Bjørn Gjelseng and Prosessmetall’s suppliers as well as clients. Taking over established working relationships requires proving your value and building trust to ensure seamless collaboration. A task Dan Stian has taken head on.

– It’s been rewarding getting to know our new clients and suppliers. It’s not an easy task to take on Bjørn’s long-time clients, his vast experience in the field of steel is impressive. Luckily, he’s taught us well in the months we have been working together, Dan Stian shares.

Football rivalries that unite the team

Dan Stian’s passion for football can rival that of Andre and Henning. His favorite teams are Liverpool FC and regional Viking FK. Mondays after match weekends are anything but dull, with friendly banter flying left and right – especially with the different allegiances in the office.

Still, when asked what his favorite part of working at Arctic Steel? The people, of course.

– We’re a team with a capital T. Everyone’s got each other’s backs, and we make sure humor has a seat at the table – it’s essential in a busy office!

With a mix of skill, humor, and a passion for helping customers succeed, Dan Stian embodies what makes Arctic Steel great. Whether he’s solving steel challenges or leading the charge on a new project, we’re lucky to have him on the team. And just as a reminder: if you’re debating soccer, tread lightly. Dan Stian plays to win!

Ensuring Trust and Quality, One Certificate at a Time

At Arctic Steel, we’re known for going the extra mile to make sure our clients get exactly what they need. But there’s one part of the job that doesn’t always get the spotlight it deserves– documentation. So, why do we put so much emphasis on it? For our clients, it’s not just paperwork. It’s peace of mind, quality control, and proof that the steel they’re getting is exactly what they expect.

Quality you can rely on

Every certificate, report, and every piece of documentation we provide comes with a purpose – to prove quality. Our clients operate in industries where there’s no room for error. Whether it’s the oil and gas sector, construction, or renewables, knowing that the material is up to standard is non-negotiable. We’re committed to delivering that assurance, making sure every batch of steel is backed by clear, verified documentation.

– We invest a lot of time ensuring our clients get the documentation they need. With every steel delivery, we compile document packets so our clients can easily verify, trace, and trust the materials they’ve purchased, says Sales and Project Manager, Dan Stian Johnsen.

Compliance without the headaches

Steel standards can be a maze of regulations, and each industry has its own. That’s why we handle the nitty-gritty, ensuring all our materials meet the right standards, locally and internationally. For our clients, this means one less hurdle to jump and more confidence that the steel they’re putting to work is ready to perform.

Traceability – knowing the journey of your steel

In any business, traceability is key, and in steel supply, it’s a game-changer. Every piece of steel we deliver can be traced back through our documentation, down to its origin. For our clients, this means that if questions or issues arise, the path to answers is clear and direct. It’s another layer of reliability that we’re proud to offer.

Building trust, one document at a time

Our job doesn’t end when the steel leaves our doors. We’re dedicated to making the entire process smooth and transparent, right down to the paperwork. Documentation might not be glamorous, but it’s what lets us – and our clients – sleep easy, knowing everything is up to code and ready to perform.

For us documentation is more than a checklist, it’s a commitment to quality, transparency, and trust. So next time you see a stack of certificates, remember – that’s Arctic Steel’s promise to you, ensuring you get the steel you need with zero compromises.

A Local Patriot On and Off the Bleachers

Say hello to our energetic Sales and Project Manager, Henning Lende!

Henning has been with us at Arctic Steel since October 2020, when he first joined the company as part of Aarbakke AS. Over time, as the steel division expanded and branched off into its own entity, Arctic Steel was born, and Henning found himself right in the middle of it all.

But Henning’s journey with us isn’t just about numbers, projects, and material logistics. His story is one of versatility and a touch of humor that lights up the office.

The return of the prodigal steel enthusiast

Henning started his career at Aarbakke AS back in 2014. Back then he stared as an apprentice in sales and earned his trade certificate by 2016. After that he broadened his horizons by operating heavy machinery at Risa AS and then later joined a start-up company selling heat pumps and outdoor hot tubs. But eventually he returned to Aarbakke’s steel department and is now thriving in his role with us at Arctic Steel, where he blends his hands-on experience with strategic project management.

To keep things even more interesting, Henning also serves part-time in the fire department. It’s safe to say that between project management and firefighting, his desk chair doesn’t get too comfortable.

The daily grind – Sales, projects, and plenty of variety

As Sales and Project Manager, Henning’s day is anything but dull. His work involves everything from calculating costs, ensuring the highest quality of materials, to working out offers and delivery times for customers.

– Every case is unique. One day, I might be working with our production partners, and the next, liaising with suppliers abroad. It’s all about making sure everything flows smoothly from start to finish, Henning explains.

Henning thrives on the variety of his role, where no two days are alike. With a wide network of suppliers and partners, he ensures customers get exactly what they need, whether it’s cutting-edge materials or additional services like drilling and machining.

When asked about the best part about working at Arctic Steel, Henning doesn’t hesitate.

– Every day is a challenge. There’s always something new to learn, especially in a growing company like this one. The people here are fantastic – great colleagues with a wealth of knowledge. Plus, it’s incredibly rewarding to make the customers happy.

The thrill of a challenge

On the subject of his favorite project, Henning can tell you about one particularly challenging request.

– We had a customer who needed material that was nearly impossible to source, with incredibly strict requirements, Henning recalls.

But with the expertise at Arctic Steel, they managed to find the perfect material and meet the exacting standards.

– It’s moments like that where you feel you’ve really made a difference – helping the customer get an edge in their business.

Football banter and steel loyalty

One thing Henning does take seriously is his football. While his colleague André may have questionable allegiances, Henning is steadfast in his support for Bryne FK, with a sharp memory for their victory over Viking FK. In fact, his favorite steel grade, AISI 420M, serves as a cheeky reminder of that win.

– It reminds all of us here that Bryne FK beat viking 4-2 last time they met in Stavanger, and that it’s been almost 24 years since Bryne last lost to viking in a competitive match, he says with a grin before he adds:

– And by the way, viking is always spelled with a lowercase ‘v’. Don’t correct that!